Producing a modern aircraft

Producing a modern aircraft can be compared to leading an orchestra – albeit one that involves thousands of participants with a reach that spans the globe. When all elements are in harmony, the synchronisation results in a system that flows and assembles the millions of pieces of our aircraft seamlessly, while giving flexibility and agility to adjust production output in response to market demand.

Bringing it all together

Each Airbus jetliner built today results from proven expertise, accumulated during the company’s 50-plus years of leadership, and constant dedication and attention from all teams. Processes are continually refined and make best use of latest technologies and best practices, keeping safety and quality at the top of our priorities.

Orchestrating the industrial flow at Airbus relies on four contributors.

- The first contributor is manufacturing engineering, which co-designs the industrial system in close coordination with engineering, and delivers solutions to the company’s various manufacturing functions.

- Secondly, the planning, transportation and logistics teams are focussed on designing and deploying integrated standards and solutions with the goals of maximising efficiency while minimising environmental impact. They take care that all pieces, parts, components are where they should be when they should be, and that the aircraft flows through our system smoothly and predictably.

- Quality is another critical element, with teams ensuring production at Airbus is compliant with industry norms, and its aircraft meet the strict standards established by international airworthiness authorities. They assess and safeguard operations, keeping the company culture focused on safety, quality and compliance.

- The fourth element involves strategic sourcing and the supply of goods and services. As partners and suppliers are considered an important part of Airbus’ extended family, the company’s teams are ready to work with them in innovating and identifying areas for improvement, ensuring that the aircraft takes good shape, months before its pieces enter our factories.

Major components and aerostructures production

Airbus has more than 20 manufacturing sites, each producing and/or assembling different parts of the aircraft – which subsequently are shipped to final assembly lines where the complete aircraft takes shape. These plants rely on thousands of suppliers worldwide, who produce roughly 80% of the aircraft, before it enters our premises.

Some plants focus on the manufacturing of elementary parts or so-called metallic or composite detail parts, tubes, pipes, panels, floors, shells, … which are used in large quantities in an aircraft. Others focus on specific functional parts and produce elements that include flaps, slats, and other high-lift devices for the wings; horizontal tail planes and rudders; and pylons that connect and support jet engines on the aircraft’s wings.

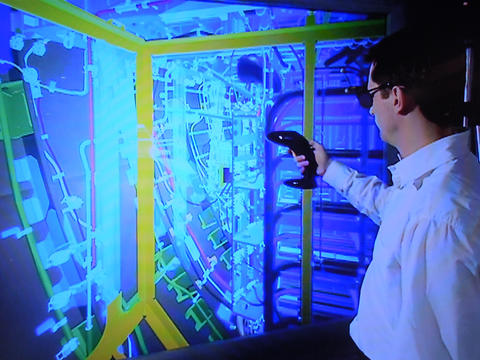

All these elementary pieces or components find their way to designated plants where large sections of the aircraft are being put together and equipped (with relevant material and systems for electricity, fluids, air, etc). The assembly of these major airframe components divides the aircraft in 5 sections: the nose, the forward section, the centre fuselage, the rear section (or aft) and the wings of course. Specific locations produce each of these sections, fully equipped, facilitating their integration when arriving on the final assembly lines. In parallel, cabins, seats and engines also make their way to the final assembly lines.

Airbus’ final assembly lines worldwide

It’s a true statement that: “the Sun never sets on Airbus’ aircraft assembly sites.” The company is unique with its 12 final assembly lines at five locations globally, including in Toulouse, France headquarters – which hosts two final assembly lines for the single-aisle A320 Family, along with one each for the widebody A330 and the A350.

The A350 final assembly line features natural lighting wherever possible and a photovoltaic roof that produces the equivalent of 55% of the power needed for the building to function. During its original construction, the building also incorporated material recycled from elsewhere on the Toulouse site.

Hamburg, Germany is home to four A320 Family final assembly lines. The most recent one is home to new technologies and processes which were developed in close coordination with employees, applying the principles of Design Thinking. This resulted in a modern and much more efficient working environment, and the Hamburg experience is now being transferred to other Airbus production lines worldwide.

A320 Family aircraft are also assembled in Tianjin, China, where deliveries are made to Asian airlines, while Mobile, Alabama, USA handles the build-up of A320 Family and single-aisle A220 aircraft for customers in North America.