Our presence in the region

As one of the countries that was key to the creation of Airbus, Germany has a rich history of aircraft design and construction and is home to some of Airbus’ largest and most important operations. More than 50,000 employees working across 27 sites represent close to half of the country’s entire aerospace workforce.

Airbus’ strong German roots provide an important impetus for growth and competitiveness for both the company and Germany as an industrial location. Airbus works with thousands of external suppliers in Germany and buys goods and services valued at several billions of euros. In addition to extensive work in the commercial aircraft and rotorcraft sectors, Airbus develops cutting-edge technologies and tailor-made products that reinforce national security, including military helicopters, satellite programmes for secure military communications and the Eurofighter – Europe’s world-class multirole fighter jet.

Our products & services

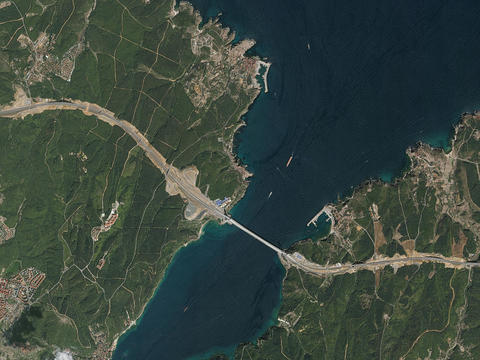

Airbus in Germany is a key player in aerospace, with major sites across the country contributing to commercial, military, and space activities. From Hamburg’s A320 Family production to one of Europe's largest military aircraft production and support centres in Manching, and Bremen’s A400M fuselage assembly and production of the European Service Module (ESM) - critical for NASA's spacecraft for the next moon missions, Airbus excels in aircraft manufacturing, satellite technology, and space exploration.

With cutting-edge research in unmanned flight, solar panels, and space systems, Airbus drives innovation and expertise across diverse aerospace sectors.

Commercial Aircraft in Germany

Our products & services

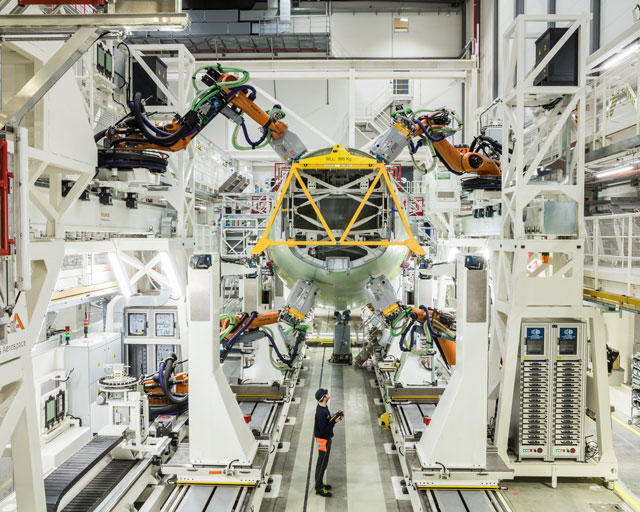

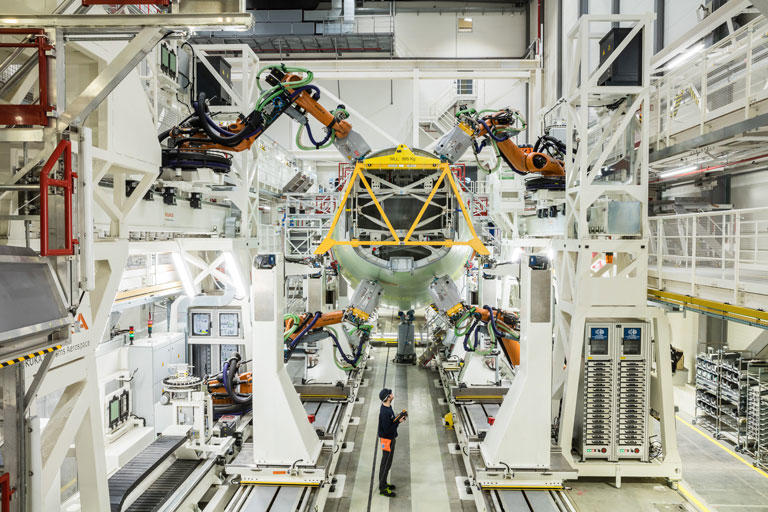

Airbus's commercial aircraft operations play a major role in Germany's civil aviation industry. Hamburg, the headquarters for Airbus Commercial Aircraft in Germany, is the largest Airbus site in the country and a key center for developing and manufacturing jetliners. With four final assembly lines as well as highly automated structure and equipment installation hangars it is home of the A320 Family programme management.

Hamburg also builds fuselage sections for both A330 and A350 programmes, along with cabin design, customer tailoring, and training services for airline staff.

Helicopters in Germany

Our products & services

Airbus' main helicopter hub in Germany is located in Donauwörth, with a workforce of more than 7,000. The site houses the final assembly line for the H135, H145, H145M and NH90 helicopters. More than 1,000 employees maintain and overhaul the Bundeswehr's helicopter fleet. Donauwörth is also home to the CityAirbus NextGen advanced air mobility prototype.

Airbus Helicopters also manufactures aircraft doors for the A320, A330 and A350 at Donauwörth. In Kassel, more than 500 employees work on the development, production and maintenance of dynamic systems.

Defence and Space in Germany

Our products & services

Manching is Airbus's center for military air systems in Germany, contributing to the Eurofighter programme with final assembly, system tests, and flight trials for the Luftwaffe. The site also supports aircraft maintenance for the German Tornado, Eurofighter and A400M fleet as well as for NATO’s AWACS E3A fleet. Research in unmanned flight, for instance on the Eurodrone, also takes place here.

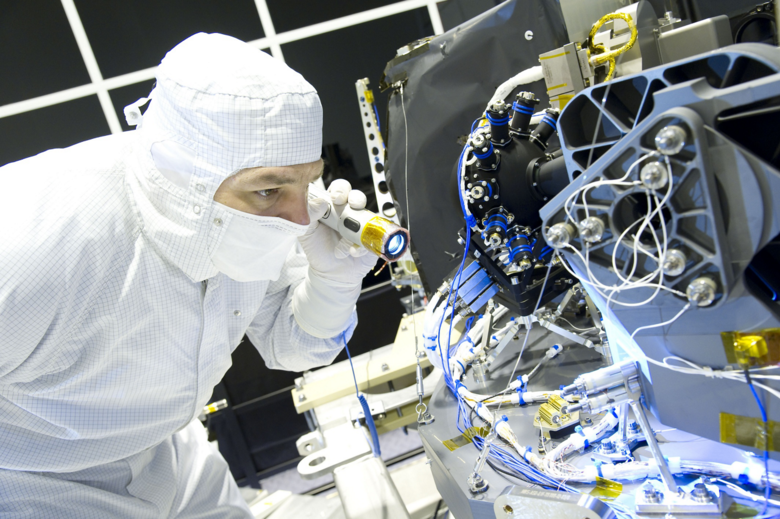

Friedrichshafen focuses on satellite development, Earth observation, and space exploration, while Ottobrunn/Taufkirchen produces optical instruments, solar panels for satellites and rocket engines. Bremen specializes in A400M fuselage assembly, space transportation, and critical components like for the European Service Module for NASA’s Orion spacecraft programme.

Innovation in Germany

Airbus is one of the world’s biggest drivers of innovation. In the recent past, it invested €3.3 billion in self-financed research and development – placing it among Germany’s 10 most research-oriented companies.

In Germany, there is considerable focus on the development of innovative technologies, such as the extraction of biofuels from algae, and Airbus holds more than 37,000 individual patents.

Furthermore Airbus, together with the European Innovation Partnership on Smart Cities and Communities (EIP-SCC) and the city council of Ingolstadt, have selected Ingolstadt as a pilot city for demonstrating various forms of digital mobility. A Manifesto of Intent was signed by Airbus and such partners as the German Aerospace Centre (DLR), Audi, Munich Airport and the Technical University of Ingolstadt.

Future talent

Airbus is committed to promoting young scientific talents. In 2012, the company launched a project at the Ludwig Bölkow Campus in Ottobrunn/Taufkirchen to enable science and industry to combine their strengths in joint research projects and promote the creation of start-up businesses. Students have the opportunity to pursue degrees and embark on research on topical issues thanks to programmes on Autonomous Systems and Green Aerospace. The campus also offers a start-up centre which facilitates the transfer of knowledge between the academic world and industry.

Apprenticeships in Germany – where dual education has a long tradition – have become an essential pillar for Airbus. The "Duales Studium" is such a programme, where students combine formal education with a more practical and specialised approach in a company for a period of three to five years.

Germany for the aerospace of tomorrow

With commercial jetliner and space activities in the northern part of the country, military aircraft business in the south, and helicopter operations in the centre, Airbus in Germany is optimally positioned for the future of aviation. Technology teams across the country are focussing on forward-looking concepts – such as unmanned and individualised air transport – that will fundamentally change the flying experience.

As a founding nation of Airbus, Germany will continue to be a key pillar for the success of the company around the world.

Local partnerships

Through partnerships with organisations like Femtec – which promotes engineering and science among female students in Germany – Airbus is encouraging students to pursue high-tech careers by inviting them to participate in technological projects within the company.

Latest from Germany

In the spotlight

-

Air policing in Romania: “With the Eurofighter we can respond at a moment's notice”

Web Story

Defence

Inside enhanced Air Policing South: German Eurofighters secure NATO’s south-eastern flank in Romania in a crucial deployment. -

Airbus ships fourth European Service Module for Artemis IV

Press Release

Space

-

Germany orders 20 new Eurofighters to strengthen air superiority

Press Release

Defence

-

Airbus opens new production hangar at its Augsburg site

Press Release

Commercial Aircraft

-

Successful launch of Airbus-built Sentinel-4 onboard MTG weather satellite

Press Release

Space