From Orion’s European Service Module, BepiColombo, Rosetta, Solar Orbiter to Juice; the Airbus team in Leiden, the Netherlands, has been delivering wings for the most spectacular spacecraft missions for over half a century. Last night however, a smallsat was launched with a set of solar arrays that are different in almost every way to what Airbus has brought to play before.

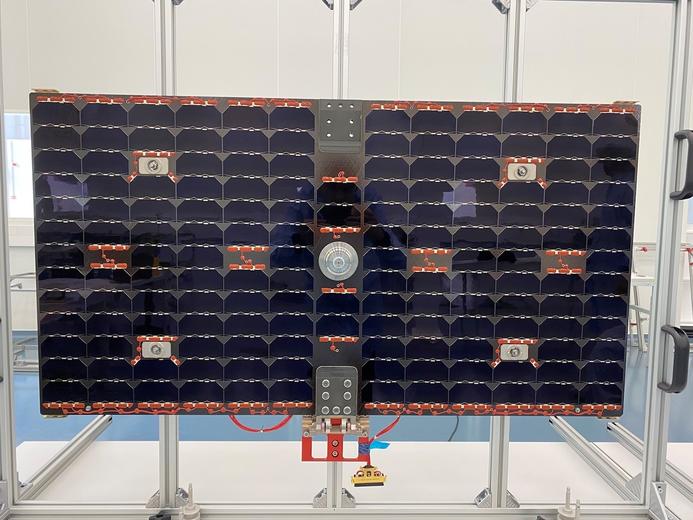

On Monday 12 June, Belgian satellite manufacturer Aerospacelab launched its first flight model of its Very High Resolution (VHR) constellation, with two single panel Sparkwing solar arrays powering it. It was the maiden flight for Airbus’ new solar array concept, which proved to live up to its promise when the Sparkwings successfully deployed shortly after launch.

Aerospacelab aims to extend its VHR constellation to more than 40 satellites. Established in 2018, the fast-growing company is specialised in satellite platforms and geospatial intelligence. The Belgian company’s venture is exemplary for today’s changing satellite market, in which multiple and smaller satellites are increasingly a go-to choice. With this part of the satellite market evolving, so too is the market for solar arrays for spacecraft. Until recently, developing solar arrays with many requirements and with extensive integration and testing campaigns was the standard. These are indispensable for missions that explore our solar system and for human space flight. Consequently, the generally large, or complex wings are costly and require time. As human space flight and science missions are important and will remain relevant Airbus will of course proudly continue to contribute to them. Still, notwithstanding the known and unknown universe, the opportunities provided by the closer-to-home New Space - or what we prefer to call #NextSpace - market are just as exciting to explore.

FOMO

With the emerging market for small satellites and with Low Earth Orbit (LEO) constellations on a quick rise, the trade-offs are weighted differently by companies selecting solar arrays for their satellites. Lower launch costs and having multiple satellites up in a constellation means that the demands for reliability are more relaxed. On the other hand, building multiple satellites means that costs have to be substantially lower and lead times shorter. Enter Sparkwing.

‘’About five years ago, we noticed that the way new market entrants acquired solar arrays was drastically different from how we were working at the time. They wanted off-the-shelf and cost efficient products. We realised that if we were unable to act on this transition, we would miss out. Airbus acted and developed Sparkwing, which demanded a totally different approach for the design and operation of the wings within a stringent time frame,’’ says business developer Chris van Remundt, who first came up with the idea for a commercially available, ready-to-use solar array.

Standardised wings

Sparkwing allows Airbus to fill a need in the current space market. Building on 50 years of experience in delivering power for international space missions- with a proud 100 percent successful deployment rate- the Sparkwing portfolio offers standardised solar arrays. Satellite builders have a choice of more than thirty different panel dimensions, configurable into deployable wings with one, two or three panels per wing. Sparkwing arrays provide high stiffness, single actuation (due to only one hold-down mechanism per wing), minimal integration made by the customer, and low demands on the spacecraft sidewall tolerances.

DIY integration

Smallsat developers can forgo a lot of development time and costs with Sparkwing. This new way of working results in some major differences in doing things. The arrays are no longer tailor-made to each satellite specifically, instead the Sparkwing concept offers a broad choice to fit all needs. Another big difference is that the integration can be done by the customer, saving time and costs on the integration and final testing of the solar arrays. Of course ample guidance is provided by the Sparkwing team in the form of something very familiar not just to aerospace engineers, but to all of us: an installation manual.

“Moving away from standard practices, Sparkwings will be integrated by our customers and not by us. Both parties want a streamlined and cost-efficient process without the risk of having an incorrectly installed wing on the spacecraft,’’ explains Mark Bakker, lead engineer of the Sparkwing team in Leiden. “It’s a bit like a DIY kit, with our manual, customers can do the installation themselves without the need to have a lot of external support.’’

Ready for large constellations

With the new space market, not only the way in which solar arrays are selected, developed and integrated is changing. New players, start-ups and #NextSpace companies ask for a different approach, which means that engaging with customers, too, is a changing game. Here, the attractiveness of the Sparkwing formula is clearly shown.

“We are on a roll. Just one and a half years after Sparkwing was qualified, we currently receive one to two requests for proposal on a weekly basis. Right now, our team is working on a batch of six additional flight models of Sparkwing solar panels for Aerospacelab. Also, customers in Asia and the US have been secured, including for missions beyond low Earth orbit. So far, nearly 40 flight sets have already been ordered overall,” says Rob Postma, managing director of Airbus Netherlands, “With the Sparkwing solar array concept, Airbus is expanding its broad space portfolio, ready for powering large constellations and ever more competitive in an ever changing world.”

Space Latest News

Continue Reading

Airbus launches demonstrator to test global 5G connectivity in orbit

Press Release

Innovation

Airbus UpNext launches Airbus UpNext SpaceRAN, a new demonstrator to enable standardised global connectivity by exploring advanced 5G NTN capabilities.

Airbus ships fourth European Service Module for Artemis IV

Press Release

Space

Sentinel-1D: the radar that never sleeps

Web Story

Space

Airbus-built SpainSat NG-II secure communications satellite successfully launched

Press Release

Space

Airbus, Leonardo and Thales sign Memorandum of Understanding to create a leading…

Press Release

Company