At the Paris Air Show, Airbus is showcasing various glimpses of the future. These can be found in a special 1,000 square metre indoor marquee called the Paris Air Lab. The Air Lab is hosted by the French aerospace association GIFAS, which represents French, European and international aerospace bodies, both public and private.

In a nutshell, Paris Air Lab opens up to the future and invites you on an extraordinary journey to discover tomorrow’s challenges: climate change, artificial intelligence, the future of mobility, and more. This event-within-an-event focuses on aerospace research and offers round-table discussions, keynote speeches, immersive experiences and other exciting activities, as well as a plethora of physical and audio-visual exhibits to discover – around 25 of which are provided by Airbus!

Through an interactive and immersive experience, visitors will have the chance to learn more about digitalisation and artificial intelligence, cybersecurity and quantum technologies, new energy solutions, future innovative aircraft, emerging air mobility concepts and more!

Future aircraft technologies: Prototypes for tomorrow’s skies

For example, in the Prototypes zone, Airbus' Wing of Tomorrow exhibit will include a two-metre folding wing model and a virtual reality experience to educate airshow audiences about how we are exploring novel wing design. We are using next-generation composite technologies that are strong and lightweight to optimise aerodynamic performance. The experience is intended to show how these wings will look and operate differently than those of today, and to spark conversations about the industrial delivery of these kinds of new concepts.

In this same area, you will even be able to ‘build your own aircraft’ on a smartphone app. This will enable you to design your own future Airbus aircraft, configuring parameters such as wings, propulsion, fuselage and even livery.

Visitors will also be able to learn about our eXtra Performance Wing demonstrator and watch a video of its first flight. The eXtra Performance Wing Demonstrator is a project led by Airbus UpNext that is focused on accelerating and validating technologies that will improve wing aerodynamics and performance, in order to reduce CO2 emissions.

And regarding CO2-saving future engines, which could take the form of an open fan engine on our future aircraft, you'll be able to learn all about how it works.

Airbus flight demonstrators on display

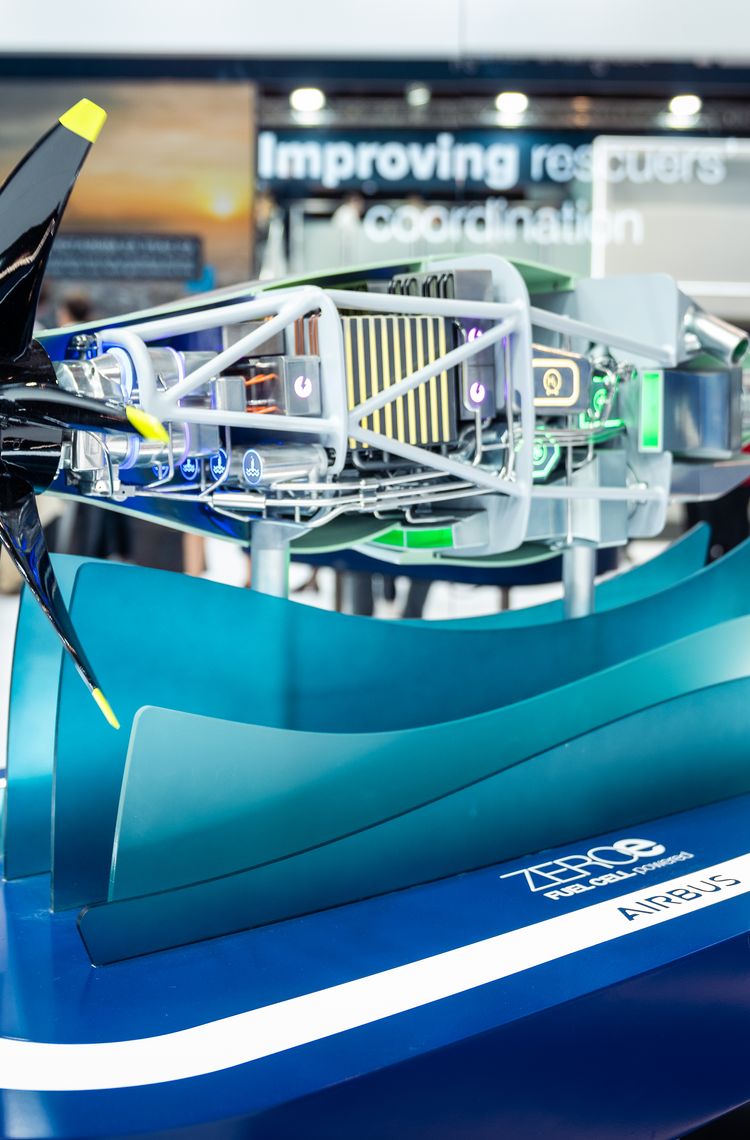

In this next section at the Paris Air Lab, Airbus has four scale model demonstrators on display: Bluecopter, RACER, the A380 open fan, and the EcoPulse aircraft.

The open fan engine represents a significant change in engine architecture, offering the potential for substantial fuel burn reduction compared to current engines. Airbus and engine partner CFM International are testing the RISE open fan demonstrator that you will see here.

Next up, the high speed helicopter that Airbus is currently flight testing, called RACER (Rapid and Cost-Effective Rotorcraft). It can fly at over 400km/h, roughly twice the speed of a conventional helicopter. This could be essential for missions where time is essential, like medical services or rescue operations. Thanks to its aerodynamic shape and optimised engines, the vehicle aims to reduce fuel consumption by up to 20%.

Staying with the helicopter theme, in the Air Lab you'll be able to find out how Airbus' Bluecopter demonstrator has played an important role in the development of Airbus’ new H140 helicopter. On Bluecopter, Airbus teams tested technologies to simplify helicopter architecture and improve performance. Key features of the H140, like the helicopter’s five-bladed rotor and T-shaped tail, are the direct result of the learnings uncovered with Bluecopter, showcasing the impact of research and technology to develop the latest generation of helicopters.

Manufacturing of the future with exoskeletons

Airbus is also developing new innovations in terms of efficient manufacturing of the future. The Air Lab will explain how we can use exoskeletons – wearable devices that support production operators – to transform manufacturing. Integrated into our assembly lines, they can offer crucial support for reducing fatigue from uncomfortable postures. This technology represents a leap forward in ergonomics, improving working conditions thanks to lightweight and comfortable designs.

Check out our pilot programme and the tangible benefits it's already demonstrating here.

Revolutionising aerospace materials

The Air Lab will show off innovative ways of using aerospace materials. An A350 titanium latch shaft made using powder bed fusion, a type of 3D printing, shows how we can reduce part count and weight in innovation. It replaces the former assembly of 10 single parts, and is 45% lighter than its predecessor. Each aircraft door on the latest generation A350 contains two of these shafts.

Airbus will also have two metal bars on display, which are the first aerospace-grade alloys made of metal recycled from end-of-life aircraft. One bar is an aluminum alloy, the other is titanium. Recycling metal of the right quality for aeronautics reduces CO2 emissions when compared to production processes using primary metals.

Airbus is also showcasing a revolutionary rotor hub for the H160 helicopter made out of carbon fiber and polyether ether ketone (PEEK) thermoplastic. This material offers improved mechanical performance, greater fatigue resistance and reduced environmental impact compared to traditional thermoset resins. Thermoplastics can replace metal hubs and reduce the overall weight and fuel consumption. This rotor hub is a great solution for up to medium-sized helicopters.

Quantum technologies: The next frontier for aerospace

Quantum technologies are set to be one of the next big game changers for the aerospace industry and are expected to create a massive paradigm shift in the way aircraft are built and flown. At the Paris Air Lab, you'll be able to gain insights on, for example, how quantum sensors are effective at measuring physical quantities that are central to aircraft operations. These include frequency, acceleration, rotation rates, electric and magnetic fields, and temperature with the highest sensitivity.

Moreover, new devices based on quantum technologies could also have various applications in improving aircraft navigation systems, in which precise acceleration measurement is used to achieve positioning data – or even by leveraging the earth’s magnetic field.

In addition, you’ll find out how quantum sensors could act as payloads for a range of different applications, such as climate dynamics from satellites or underground resources surveying from an aircraft, and much more.

Decarbonisation and new energy sources

And as a final teaser, Airbus is showcasing a range of technologies that aim to contribute to meeting the aviation industry’s decarbonisation ambition. Chief among them are promising propulsion concepts such as electrification, hybrid-powered flight and hydrogen fuel cells. In a hybrid configuration, an aircraft uses several energy sources in flight, either in tandem or alternately. The mix of energy sources optimises overall energy efficiency and reduces fuel consumption. Better energy management leads to reducing fuel consumption by up to 5% compared with a standard flight.