There is hardly a more gripping moment than launching a spacecraft – everything has to go perfectly and there is no room for error. However, getting there can be just as demanding. The success of any Airbus space mission hinges on close collaboration with UK partners, from working with world leading academia on research and development, to drawing on the expertise of specialist suppliers.

Whether it is bringing people closer together through communications, providing new perspectives on our planet or enabling us to explore new frontiers in the solar system – space technology is a powerful force for innovation, collaboration, and discovery.

As the largest space company in the UK, Airbus Defence and Space develops and manufactures space technology mainly at its key sites in Stevenage and Portsmouth. The company works closely with academic institutions and companies on research and development. Not to mention various UK suppliers.

Partnering on cutting-edge research

Academic institutions play an important role in driving and validating innovations – especially in the space sector. This also makes them essential partners for us at Airbus: in the UK, Airbus is funding various PhDs and research projects across the countries.

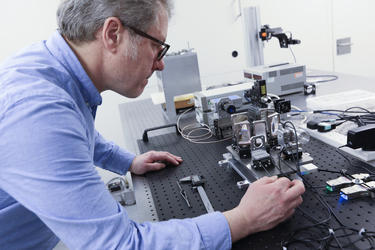

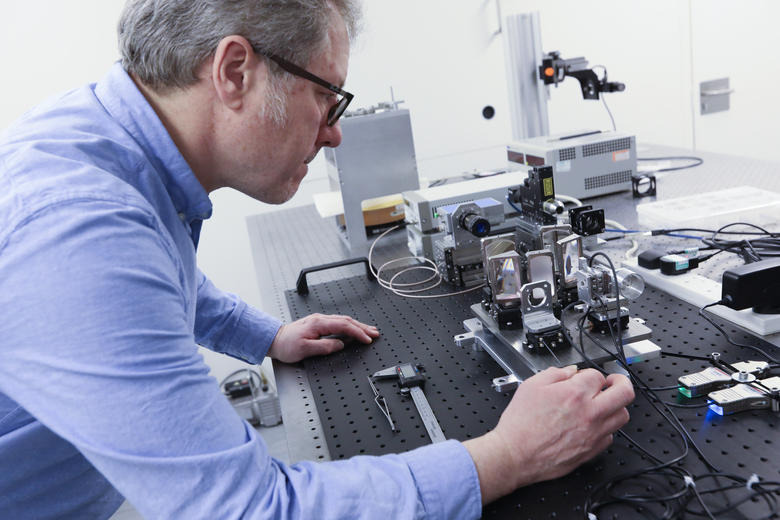

An expert in hyperspectral imaging, Wrexham University is exploring the potential space applications through its commercial arm, Glyndwr Innovations. (Image source: Wrexham University)

At Wrexham University in North Wales, for example, cutting-edge research and development of precision optics and optical systems led to the creation of a commercial arm, Glyndwr Innovations. One of its areas of expertise is hyperspectral imaging.

A hyperspectral imager is a device that takes 300 images of a scene simultaneously across many narrow spectral bands (colours). It provides comprehensive image data, allowing you to spot even the tiniest colour variations and distinguish the composition of the scene in much greater detail. It has a wide range of applications, including the detection of skin cancer in humans, blight in crops, and even the presence of mineral deposits in landscapes.

As a university, we can be a facilitator. Projects like this are what make the direction of our research both tangible and commercially viable.

Professor Caroline Gray OBE, Director of the OpTIC Technology Centre Wrexham University

Paired with satellite imagery, hyperspectral imaging can also play a major role in environmental monitoring, as Professor Caroline Gray OBE, Director of the OpTIC Technology Centre at Wrexham University is well aware. “Tracing pollutants in air, water and soil, or detecting disease and insect infestations in forests are just a few examples of how we can benefit from hyperspectral imaging from space," she says.

To further explore this potential, Glyndwr Innovations joined forces with Airbus. So far, the partnership has produced a lab based technology demonstrator that proves the system works as expected. "The next step will be to produce a flight-ready system," Gray says.

For Professor Gray, this collaboration is a prime example of how the relationship between academia and industry should work: "As a university, we can be a facilitator. Projects like this are what make the direction of our research both tangible and commercially viable. This in turn helps us build our reputation and fund our work, while at the same time contributing to the growth of the skills and knowledge needed by the UK industry.”

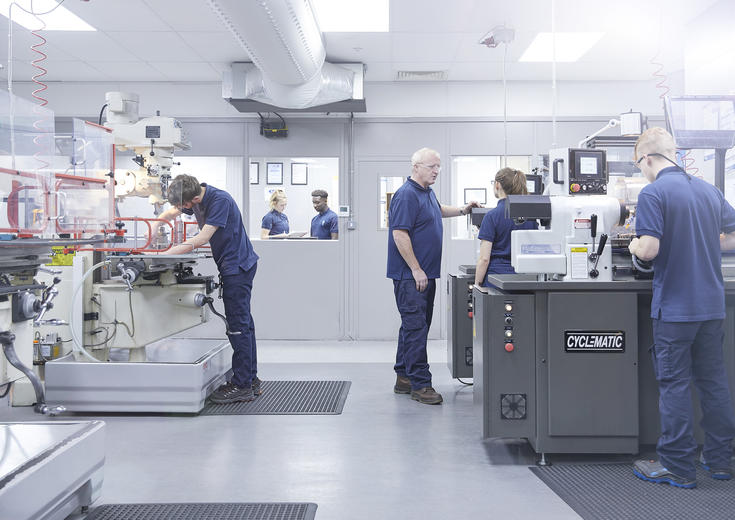

The apprentice training school of Reliance Precision in Huddersfield, UK. (Image source: Reliance Precision)

Developing new products and technologies

Developing new products for the space industry can come with a steep learning curve, making collaboration a must. That is why Airbus is working with businesses across the UK to co-develop new space technologies.

A company that has recently increased its involvement with the space sector is Reliance Precision. Based in Huddersfield, UK, the company has over 100 years' experience in manufacturing high quality gears and precision actuation components.

As a specialist manufacturer, the company works with customers in a variety of industries, but space was more or less new territory for them. "Back in the 90s, we made a large Solar Array Drive Mechanism gear that was later used in the Rosetta probe to chase down Comet 67P,” says Andrew Butt, Head of Business Development & Commercial.

In the space sector there is a real sense of cooperation and consistent support that I haven't experienced in any other industry.

Andrew Butt, Head of Business Development & Commercial Reliance Precision

In 2017, a new challenge arose for Reliance Precision when Airbus approached the team to develop a new stepper motor gearbox (SMG) for Airbus Stevenage’s solar array drive mechanisms. In brief, this motor is responsible for pointing the solar arrays of large geostationary satellites towards the sun. This resulted in the development of the NeoSMG for the Eurostar Neo based satellites, which was first launched into space in October 2022 as part of the Eutelsat HOTBIRD 13F.

"Our thought right from the start was: 'This project is literally written in the stars for us,'" Andrew Butt says. But at the same time, the project meant a big change in the way Reliance Precision worked. “We had to deeply engage with the unique requirements of the space sector and adapt our product assurance and quality standards to its needs.”

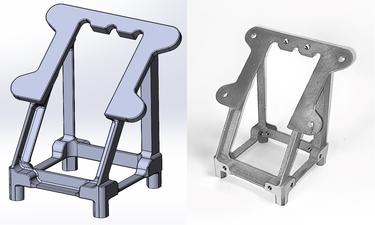

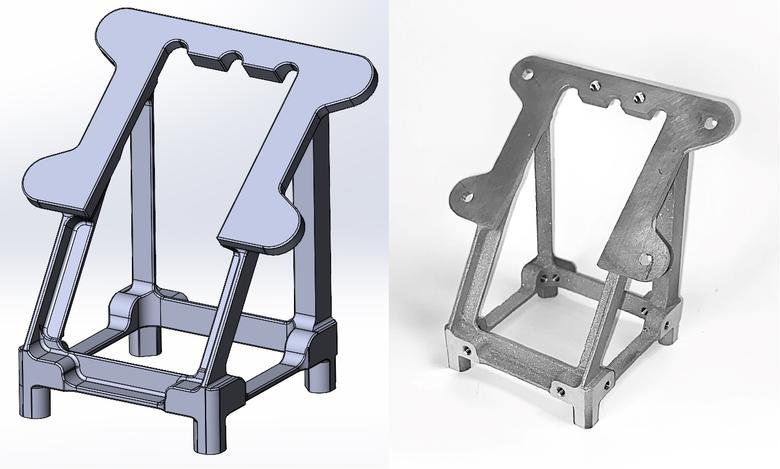

Together with Airbus, Reliance Precision developed the NeoSMG, a stepper motor gearbox for Airbus Stevenage’s solar array drive mechanisms. (Image source: Reliance Precision)

In the end, Reliance Precision went through a huge learning curve – an experience Andrew Butt would not want to miss: "Compared to other industries, I was surprised at how collaborative the relationships are. There is a real sense of cooperation and consistent support that I haven't experienced in any other industry.”

Looking towards the future, Reliance's space journey has only just begun: the company has secured a second space contract with Airbus to produce a further 26 NeoSMGs.

Leveraging the UK supply chain

Building spacecraft is a big team effort. For all its space missions, Airbus Defence and Space relies on expertise and high-tech components from all over the UK – provided by more than 2,000 approved suppliers, more than 50 per cent of which are SMEs.

To make the most efficient use of fuel and to keep launch costs down, the parts of a spacecraft have to be as light as possible, while still being able to withstand the enormous forces they are subjected to.

Tritech Group - a long running partner of Airbus - has developed a process that combines advanced engineering and casting techniques to produce lightweight, high-strength components, which are ideal for orbital applications. (Image source: Tritech Group)

Headquartered in Wrexham, North Wales, Tritech Group – an expert in investment casting – has a solution for this. Dubbed “Enhanced Properties Investment Casting” (EPIC), the company has developed a process that combines advanced engineering and casting techniques to produce lightweight, high-strength components for satellites and other applications.

"The parts we produce have superior mechanical properties at the weight of aluminum, making them ideal for orbital applications," explains Kimberly Northover, Business Development & Marketing Manager at Tritech. The company has contributed components to various space missions already. “We work in partnership with our customers, offering design and manufacturing advice and collaborating to find joint solutions.”

Working across the civil, defence and space sectors, we are in a perfect position to identify best practices and promote knowledge sharing.

Kimberly Northover, Business Development & Marketing Manager Tritech Group

Tritech has long been a loyal supporter of Airbus. It all started 40 years ago in the Commercial Aircraft business. Since then, the relationship has expanded to also cover the defence and space sectors. "This diversification allows us to showcase that we are a trusted partner across a wide variety of sectors,” Northover says. "There is also a lot of synergy. Working across the civil, defence and space sectors, we are in a perfect position to identify best practices and promote knowledge sharing – which ultimately benefits Airbus."

Going forward, Tritech is looking to further develop its manufacturing techniques and drive innovation. “Airbus is shaping the future of aerospace and we are excited to be part of it.”

More on Airbus in the UK

With more than 25 sites stretching from Aberdeen to Portsmouth, Airbus makes an extensive contribution to the UK – not just in the space sector, but also with regard to civil aerospace, military aircraft and helicopters. All of this, while relying on diverse skills, advanced technologies and facilities that only the UK can provide.

Latest News

Continue Reading

Artemis II: Why we are going back to the Moon and why it matters

Web Story

Space

Artemis II launches soon! 4 crew will fly round the Moon in the Orion/ESM. The programme aims to establish a sustained long-term human presence on the Moon

Airbus and Hisdesat sign a commercialisation agreement for PAZ-2 satellite imagery

Press Release

Space

The first Airbus Pléiades Neo Next satellite will be launched early 2028

Press Release

Space

Airbus launches demonstrator to test global 5G connectivity in orbit

Press Release

Innovation

Airbus ships fourth European Service Module for Artemis IV

Press Release

Space