Exoskeletons aren’t limited to the imaginary worlds of superheroes like Iron Man. They are a reality on final assembly lines for Airbus aircraft, where they reduce fatigue for workers and help to prevent musculoskeletal disorders.

Manufacturing aircraft inherently involves physically demanding work from those on the final assembly lines. As safety is always the highest priority, Airbus is committed to constantly investigating ways to reduce operator fatigue and injury risk, as well as improve comfort.

One such solution that is currently under study at Airbus is exoskeletons, which are wearable devices that act as an external skeleton for the operator, providing additional support and relieving pressure on muscles. While exoskeletons in movies appear as powerful do-all supports that can handle any task, most industrial exoskeletons are precisely designed to support one single part of the body or assist with one specific type of task.

Evolution of exoskeletons in manufacturing

Despite exoskeletons’ exciting sci-fi appearance, there were initially significant doubts about them from medical providers in the early 2000s, due to a lack of data and concerns about the devices simply shifting pain points. Early exoskeletons were also bulky and often powered, which meant they required heavy batteries that made them less comfortable.

Yet over the past five years, several positive developments have led to a change in perspective. First and foremost, studies from INRS (the French National Research and Safety Institute) and its Canadian counterpart, the IRSST, provided guidance about deploying exoskeletons in working areas and the positive benefits they can bring. This supported benchmarking data from other industries about the successful use of exoskeletons, and came at a time when the devices were becoming lighter and easier to adjust. The focus for industrial purposes has also shifted from powered exoskeletons to passive ones, meaning they are purely mechanical and do not require batteries.

Despite these positive results, no one at Airbus is forced to use an exoskeleton if they do not want to. The Company sees these devices as a last resort used when other ergonomic solutions – reducing loads, task rotation, assistive devices and more – are not feasible or sufficient. Thus the current pilot programme is operating on a volunteer basis, with the choice of using an exoskeleton coming from the operator.

Testing the waters with an Airbus exoskeleton pilot programme

Airbus is taking a cautious, operator-focused, and data-driven approach to integrating exoskeletons into its processes. As part of the pilot programme, 118 exoskeletons are currently being tested at Airbus across France, Spain and Canada, with more test campaigns planned for Germany, the United Kingdom and the United States in the months to come. Each exoskeleton is tested onsite by a single operator for two to three months, with operators performing tasks both with and without the exoskeleton to compare data. They also provide regular feedback via questionnaires.

This pilot programme is primarily investigating how exoskeletons can relieve stress on three different areas of the body: shoulders and neck, lumbar and knees. Airbus’ medical department is measuring their impact on muscle activity through electromyographies, as well as monitoring heart rate.

In May 2025, a test demonstrated that two paint shop operators experienced a 10% to 40% decrease in shoulder and upper back muscular strain when sanding while wearing exoskeletons. The sanders weigh two to three kilos and are held over the head for long periods. “These results are very satisfactory,” says Dr. Delphine Bouvet, who led the study within Airbus. “They confirm that an exoskeleton can in some cases provide support and comfort to the operator, all while reducing the arduousness of certain tasks such as sanding.”

Scaling the use of exoskeletons

This is only the beginning for exoskeletons at Airbus. As protocols are matured and more feedback is gathered, the Company can better plan the logistics of a large-scale deployment, as well as collaborate with suppliers to improve existing exoskeletons for aerospace purposes based on operators’ feedback.

Exoskeletons will form a key part of the toolkit in Airbus’ larger ergonomic strategy, supplementing the improvements provided by other solutions such as FlexTrack robots, zero-gravity arms, and collaborative robots like CABI, a marking robot that reduces kneeling time for operators.

Robots will never replace operators, but instead will support and facilitate their work. While it is true that in the future they will increasingly take over tasks that are uncomfortable or repetitive, this will have a net-benefit effect for operators, who will be retrained to work on more exciting and complex operations.

Media gallery

Discover more Innovation news

Continue Reading

Web Story Innovation

Powering production and protecting people with exoskeletons

Discover how Airbus is revolutionising aircraft production with industrial exoskeletons that improve ergonomics and safety for workers.

Press Release Innovation

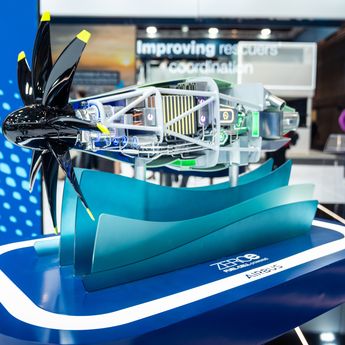

Airbus and MTU Aero Engines advance on hydrogen fuel cell technology for aviation

Press Release Innovation

Airbus and Critical Software explore strategic partnership in embedded software…

Press Release Defence

Strengthening Europe's sovereignty: Airbus and Quantum Systems work on ecosystem for…

Web Story Innovation

Airbus at Paris Air Lab 2025: Discover Tomorrow, Today