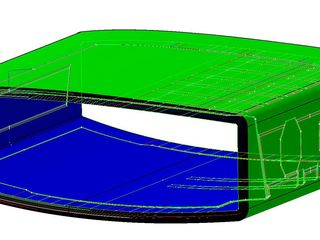

Underscoring its role as an innovation leader, Airbus has created the first-ever single-piece composite centre wing box – representing an important evolution of this vital structural component that provides support and rigidity for an aircraft’s wings.

It was designed by research and technology teams at Airbus’ Toulouse and Nantes facilities in France as an upgrade to conventional multi-part centre wing boxes, with advantages of the new version including a 20 per cent reduction in manufacturing costs.

The single-piece composite centre wing box fully leverages advances in composite technologies, including the moulding of complex parts combined with continuous fibre. This makes it easier to assemble, and provides improved load-bearing properties.

According to project leader Denis Soula, the initiative – which already has demonstrated its feasibility – was assisted by external partners, including STRUCTIL and JAMCO, both developers of preform production technology; and carbon fibre lay-up specialist CORIOLIS.

The teams’ next objective is to prepare the single-piece composite centre wing box for industrialisation using a full-scale demonstrator, with the goal of readying it for use on next-generation aircraft.

It was designed by research and technology teams at Airbus’ Toulouse and Nantes facilities in France as an upgrade to conventional multi-part centre wing boxes, with advantages of the new version including a 20 per cent reduction in manufacturing costs.

The single-piece composite centre wing box fully leverages advances in composite technologies, including the moulding of complex parts combined with continuous fibre. This makes it easier to assemble, and provides improved load-bearing properties.

According to project leader Denis Soula, the initiative – which already has demonstrated its feasibility – was assisted by external partners, including STRUCTIL and JAMCO, both developers of preform production technology; and carbon fibre lay-up specialist CORIOLIS.

The teams’ next objective is to prepare the single-piece composite centre wing box for industrialisation using a full-scale demonstrator, with the goal of readying it for use on next-generation aircraft.