Increased demands in performance and production rates require a radical new approach to the design and manufacturing of aircraft wings. In Filton, a multifunctional team is working to create the wing of the future.

No one can be quite sure how the next generation of aircraft wing will be. It may be shaped differently or assembled in a new way. It could be made of composite or advanced metallic materials. However, one thing is for sure: with aircraft production rates set to ramp up significantly, wings will need to be faster, easier and cheaper to make and assemble.

With such a range of factors to consider, creating the wing of the future will be no easy task. This is the challenge facing Airbus’ Wing of the Future programme, which will explore the best materials, manufacturing and assembly techniques, as well as new technologies in aerodynamics and wing architecture. Set up in 2015 and based in Filton, UK, this multifunctional team will select and develop a range of innovations in preparation for full-scale demonstrations.

“There are a number of reasons behind setting up the programme now,” says Tim Galsworthy, who is leading the team. “We need to ensure our aircraft perform as well as they can in the future, particularly in terms of fuel efficiency. And we also have to be able to meet new production rate targets. This is totally new ground for the industry.”

With this in mind, the Wing of the Future programme has engineering and manufacturing teams working closely together. “It’s all interlinked: we have to design the product alongside the factory. Stand-alone solutions may look good on paper, but everything has to fit together,” says Galsworthy, who has worked on the A380, A400M and A350 XWB during his time at Airbus.

New materials represent a major part of the programme and the team is already looking at lower-cost composite technologies. This could enable wing components to be produced with significantly reduced equipment and tooling costs, along with enabling a faster production cycle.

A greater use of composite materials also opens up new possibilities in terms of wing configuration and construction as fewer individual components are required. Airbus is working closely with the UK’s National Composite Centre (NCC) for this project in a bid to “push the boundaries of composites manufacturing way beyond the current capabilities”, says the NCC’s Aerospace Lead Steve Suddell. “It’s exciting for us to work so closely with Airbus’ brilliant engineers to develop completely new manufacturing processes. This is a once-in-a-generation opportunity that could have a widespread impact: what the aerospace industry does today, other sectors will do in several years’ time.”

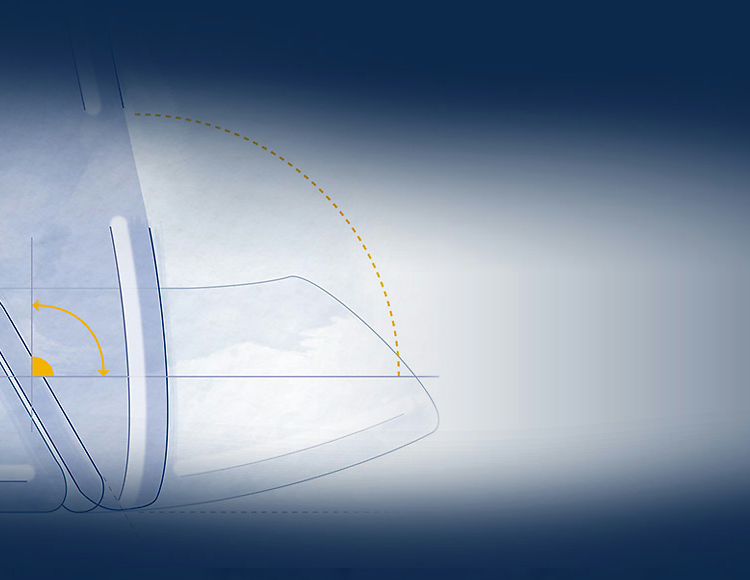

The programme will also investigate different wing sizes. Long, narrow wings can offer a high lift-to-drag ratio, which could improve fuel efficiency. However, wing length is restricted to a maximum length by airport regulations, which is why the team is experimenting with folding wing tips that could be extended before flight and folded back on the ground. Whether the gains in aerodynamic performance outbalance the extra weight and cost remains to be seen, says Galsworthy.

Helping the Wing of the Future team to perform such diverse and extensive testing is the recently announced Airbus Wing Integration Centre at Filton. Due to open in 2018, the facility will provide a state-of-the-art environment for Airbus in the UK, its suppliers and academic partners.

Investment comes from the UK’s Aerospace Technology Institute (ATI): “We want to ensure the UK maintains its leading global position in wing development. Locating the centre at Filton enables us to build on the expertise and experience that is already there,” says Dr Simon Weeks, CTO at the ATI.

It’s too early to say precisely what this expertise and experience will produce in its search for the wing of the future. But as Galsworthy says, this is a project with a long-term mindset.

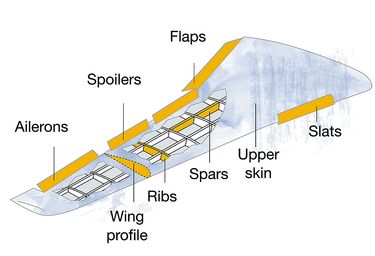

All you need to know about wings

While the basic parts always remain the same, wings come in many shapes and sizes. It all depends on the job the aircraft is designed to do. Planes with long and narrow straight wings use less fuel since they can glide better, but are not suited to quick manoeuvres. Aircraft with swept wings are very agile at supersonic speeds, but are no match when it comes to endurance.

The history of aircraft wings

Aviation history expert Richard Gardner speaks about how the shape of wings have evolved over the last several decades.

Many of the first powered aircraft in the early 20th century were biplanes with two wings stacked one above the other – why was this?

A double wing provided extra lift without making the aircraft too big and provided a stiffer wing structure. At the time, aeroplanes only had enough power to lift the pilot and the aircraft. During the 1930s, metal began to be used more frequently instead of wood and fabric, and as speeds and therefore aerodynamic drag increased, biplane designs were gradually phased out.

What was the next major milestone in wing development?

By the end of the Second World War, we had jet-powered aircraft. This saw a huge increase in speed and higher altitude flight, so strength and performance requirements changed, resulting in new wing shapes, including swept wings, delta wings and crescent wings. All required extensive new aerodynamic research and testing in high and low-speed wind tunnels to produce aerodynamically efficient wings and empirical data to be entered into computer models to allow designers more flexibility in wing design.

Who were the most influential figures in wing development?

German scientists Johanna Weber and Dietrich Küchemann working alongside other British scientists at Farnborough, carried out groundbreaking research in the UK after the Second World War. They identified, amongst other things, the junction of the wing and the fuselage and the shape of the wing tip as chief sources of aerodynamic inefficiency. Their work led to the development of Concorde’s unique wing in the 1960s and then the Airbus A300 in the 1970s, which was the first ever twin-engined widebody airliner. The advantages this wing design offered over its rivals in terms of performance and fuel efficiency were probably the most crucial aspect in Airbus’ early success, and this continues to this day in the present Airbus designs.

Geoff Poulton