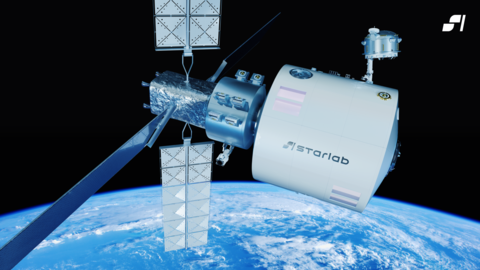

When the International Space Station (ISS) comes to the end of its lifetime at the end of this decade, Airbus aims to have its successor up and running: Starlab, the next generation Space Station designed to ensure a continued human presence in low-Earth orbit and a seamless transition for microgravity science and research from the ISS into the new commercial space station era.

To achieve this, Airbus, U.S.-based Voyager Space and Japan’s Mitsubishi Corporation have formed the Starlab Space LLC international joint venture to design, build, and operate the Starlab commercial space station. Starlab’s goal is to serve a global customer base of space agencies, researchers and companies large and small.

A new ecosystem for space cooperation

Starlab will be lofted prior to the International Space Station’s decommissioning, with the capacity to conduct more than 400 experiments or technical investigations per year. It will serve as a foundation for continued international cooperation in space – accelerating a space ecosystem 400 km above the Earth.

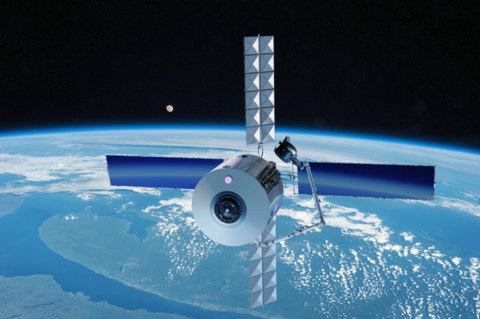

An important design feature for Starlab is its ability to reach orbit as a fully functional facility on a single flight of a super-heavy launcher: the SpaceX Starship has been selected for this historic launch. This “no assembly required” strategy is in contrast to the International Space Station (and other contemporary space station concepts) which need to be built over a period of years by linking up building-block modules in orbit.

At the heart of Starlab is the Airbus LOOP multi-purpose orbital module. In this design, multiple decks, connected by a central tunnel surrounded by a greenhouse, will give astronaut sample space for their science and research as well as their exercise and free time – including the view from windows of an unprecedented dimension in any spacecraft before. Designed for a crew of four, it can temporarily accommodate up to eight astronauts, e.g. during crew rotation periods. The steel-cased module of approximately eight metres in height and diameter offers maximum protection in the harsh space environment while ensuring a 30-year lifetime. It will also comprise a smaller Equipment Bay Module with storage, support systems and hygiene facilities, while the Service Module provides 60 kW of power as well as propulsion.

To provide a sense of “home away from home” and optimise use of the space, the Hilton hospitality team was selected as Starlab’s partner, supporting the design and development of crew suites, communal areas and more aboard.

Benefitting from Airbus’ experience in human spaceflight

The development of Starlab benefits from Airbus’ extensive expertise in human spaceflight, including the Columbus module that is a key element of the current International Space Station. Produced by a consortium of companies from 10 European nations under Airbus leadership, the capabilities of Columbus were enhanced with the addition of the Bartolomeo platform – built and operated by Airbus to host external payloads with such applications as Earth observation, astrophysics, robotics and material science experimentation.

Airbus also designed and built five 20t Automated Transfer Vehicles (ATVs) that were sent to the International Space Station as cargo resupply spacecraft from 2008 to 2015. The ATV followed the company’s Spacelab laboratory that was carried 22 times by Space Shuttles beginning in 1983.

Looking to the future, the Airbus-built European Service Module (ESM) is one of the core elements of NASA’s new Orion spacecraft – the U.S. spacecraft that will return humans to the Moon later this decade.

The LOOP multi-purpose module

With its modular design, customers can adapt LOOP’s multi-deck selection to their individual mission requirements and objectives