Industry 4.0

A future-focused, intelligent and digital industrial ecosystem

Building the future of aviation

Changing market needs, technology advances and customer expectations are radically transforming the way today's aircraft are designed and manufactured. To build aircraft at ramp-up pace that meet the highest standards, Airbus’ industrial ecosystem must be future-focused, intelligent and digital.

Welcome to Industry 4.0, a fully connected and intelligent industrial system that is revolutionising every aspect of the aerospace lifecycle. This digital transformation is key to boosting flexibility, improving quality, and delivering the future of flight, sustainably and efficiently.

What does Industry 4.0 mean for aerospace?

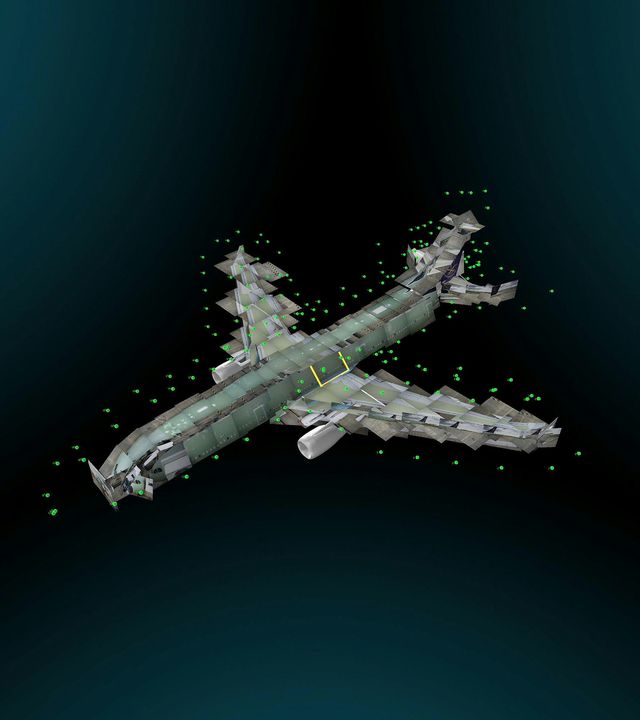

Industry 4.0, often called the fourth industrial revolution, represents the full-scale digitalisation of manufacturing. For Airbus, it means creating a so-called ‘smart factory’ ecosystem, where connected machines, robotics and artificial intelligence work in harmony with shopfloor operators.

By harnessing the power of data, we are creating a digital thread that runs from initial aircraft design and supply chain management through to production and in-service support. This approach allows us to be more agile, predictive, and efficient.

Industry 4.0 in action: The A321 Final Assembly Line in Toulouse

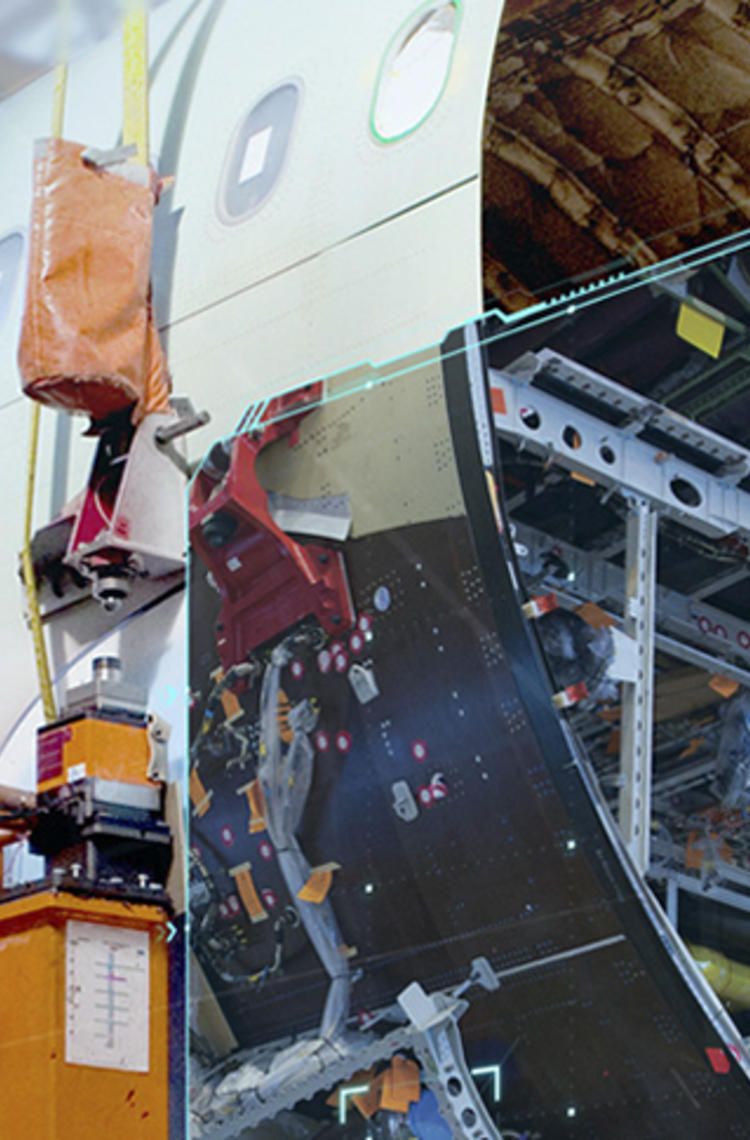

Inaugurated in 2024, this state-of-the-art, new generation and digitally-enabled A321 Final Assembly Line (FAL) in Toulouse is a window into the future of aircraft assembly.

The facility in Toulouse provides Airbus with increased production flexibility, leverages new levels of efficiency and offers an improved industrial flow with a strong focus on quality, employee ergonomics & safety.

The new line is located in the former A380 Lagardère facility in Toulouse, making perfect use of the 50 hectare facility - whose production halls are the size of 500 tennis courts. Operators have constant access to data via mobile devices, in a paperless environment. Other innovations include automated drilling and logistics.

The latest in Industry 4.0

In the spotlight

-

The Future is Calling: Unveiling Airbus' Private 5G Network

Web Story

Innovation

Airbus’ digital transformation is taking another leap forward thanks to the deployment of its private 5G communications network. -

Can the tracking of in-flight catering improve airline sustainability?

Web Story

Commercial Aircraft

-

In space manufacturing and assembly

Web Story

Space

-

Industry first: Loft Orbital signs agreement with Airbus to procure more than…

Press Release

Space

-

Clever connections

Web Story

Innovation