The A330neo has the highest wingspan and aspect-ratio for any widebody airliner in its category – making it one of the most aero-efficient airliner wings ever.

When you look at the A330neo’s new wing from any angle, you will immediately notice how long and aesthetically slender it is – continuously from its root all the way to the tip. This is no coincidence. Indeed, as airliners have become ever more efficient, the trend in wing design has been to reduce the ‘standard mean chord’ – the average distance between the leading edge and trailing edge along the airflow direction – in relation to the increased span.

Together these factors determine the wing’s “aspect-ratio”, which is measured as a function of wing span and area: the greater the wingspan for a given wing area, then the greater the aspect-ratio. The benefit of this on the A330neo is lower induced drag and higher lift at all speeds and flight phases. In other words, this means greater aerodynamic efficiency leading to lower fuel burn, less CO2, more range and of course more revenue-generating payload. And this has resulted in a beautiful wing too!

Maximised wingspan and industry-leading aspect ratio

When comparing the overall length of the aircraft with its wingspan, whereas in the past the length of the aircraft tended to be greater than its wingspan, today, in contrast, the wingspan can be equal to, or even exceed the fuselage length. For the A330neo, its wingspan is as wide as the fuselage is long – around 64m!

It should be noted that wingspan, for all intents and purposes, has now reached its practical limits on widebody aircraft due to the physical constraints of the airport gates where the aircraft are parked adjacent to other aircraft. If it wasn’t for this gate constraint, then the A330neo’s wing could in theory have been designed with even more span. Nevertheless the Airbus design team in Filton, UK, succeeded in achieving a very impressive aspect ratio, reaching a record value of almost 11! By comparison, most other modern airliners in production today have managed an aspect ratio of only around 9 or 10. So in this respect, the A330neo really is leading the field by a significant margin.

Computer designed and modelled as a complete package

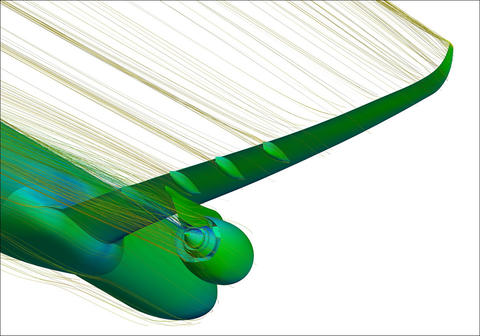

Furthermore, as the A330neo’s wing was the most recent to be designed, it has benefitted from the very latest generation of three-dimensional computational fluid dynamics (CFD) tools. These have enabled very fine optimisation of the wing twist, such that the airflow’s angle-of-incidence is optimised at every point along the span from root to tip, even as the wing slightly rotates while naturally flexing in flight.

The net result is to achieve what we call an “elliptical spanwise lift distribution” along the A330neo’s entire wing. Moreover, the CFD also modelled in 3D to include the new large engine nacelle as well as the composite belly fairing. In doing so, all the wing’s aerodynamics and aero-elastic characteristics have been modelled and optimised as a complete package – a practice which Airbus had pioneered with its A350’s wing development.

Latest evolution of performance-enhancing wingtip technology

The other thing to notice are the A330neo’s upward curving and swept back wing tips, which are similar to what we see on the A350. By comparison, up to the 1980s the wings used to stop rather abruptly at the tips – apart from maybe some rudimentary ‘rounding-off’ such as with a 2D Küchemann-style tip at the very extremity. Then for the next two decades we would see sharply canted winglets attached to the ends of the wings of numerous airliners and business jets. Coming to the present day, on the A330neo we see even more span, with the tips now smoothly tapering and curving up almost to a fine point – similar to how a bird’s wings curve upwards at the end. In fact, on this modern and efficient wing the geometry transitions are noticeably smooth, from the main part of the wing all the way right to the end of the tip – again helping to maximise lift and reduce drag.

Function and form

In a nutshell, the A330neo’s embodies all these latest evolutions in wing design: maximised span in relation to the wing area, plus finely tapered curved wingtips, continuously optimised wing twist, and all modelled and optimised in 3D together with the engine using the most powerful computational design techniques. Overall, the A330neo’s wing is a perfect blend of function and form.