Artificial intelligence for the aerospace sector

It looks for tumours, composes music and even drives cars: artificial intelligence – or AI for short – is a technology that’s currently changing the lives of each and every one of us. But what role does it play in an aerospace company like Airbus?

Chatting with Rose is really good fun – at least to begin with. She talks about her life in San Francisco, her two chickens and her pet cat. She comes across as funny, quick-witted and interested in what you have to say. But as the conversation proceeds, she turns out to be a rather poor conversationalist.

Whenever she can’t think of an answer to a question, she tries to change the subject with a question of her own. And when she gets bored, she threatens to end the conversation altogether. Still, it’s hard to get annoyed with her. After all, Rose isn’t a real person. She’s a chatbot. (You can meet Rose yourself at bit.ly/bot_rose).

It’s still early days in the development of chatbots – with ‘still’ being the operative word. That’s because AI is making them smarter all the time. Companies such as Google, Apple, Facebook, Amazon, Microsoft and IBM are working flat out to perfect their bots. It’s only a matter of time until they become a part of our everyday lives in the form of virtual assistants or customer service agents.

AI is also changing many other areas of our lives: it can diagnose cancer, operate cars, predict crime – and is therefore causing a huge amount of hype, particularly among major technology companies. But how relevant is this trend for an aerospace company? What potential does AI hold for Airbus?

Time to play a board game

To find out, FORUM paid a visit to the Airbus site in Munich where Ronny Fehling, head of data-driven technologies, has his office. Before starting at Airbus a year ago, the computer scientist worked in Silicon Valley, and with the big bean bags in the corridor and two of his colleagues playing table tennis in the office next door, there’s certainly a hint of Silicon Valley here.

Sitting in his office, he attempts to explain what AI is all about. It’s a tricky question – there are at least as many definitions of AI as there are experts in the field. Even Fehling has his very own definition: “Until something works, we call it AI. As soon as it works properly, it’s just an algorithm,” he says with a smile.

Put simply, AI could be described as the attempt to make machines think like humans. It’s an idea that’s more than 70 years old, and Airbus has long had AI applications. Airbus Helicopters has been using an artificial neural network since 2005 to adjust its rotor blades. Some years ago, however, AI was given a new lease of life, explains Fehling.

Deep learning, which is a system based on a deep neural network, is what’s responsible for this, he says. This network is modelled on the human brain and is ‘deep’ due to its numerous layers. You feed this network with data and examples, which it then processes, thus acquiring knowledge.

And it does so with a great deal of success. In March 2016, Lee Sedol – a South Korean champion in the Asian strategy game Go – was challenged to a match against the Google software AlphaGo.

Go is described as one of the world’s most complex games of strategy, and Google’s programme surprised its opponent with moves that no human had ever made before. It won the match 4-1, leaving behind a shocked Lee Sedol and the realisation that artificial neural networks with the capacity to learn are able to find their very own, completely new solutions. This makes the technology particularly interesting for several sectors, and Airbus is also exploring the new opportunities AI opens up.

However, as Fehling explains, it’s not just about jumping on the bandwagon and chasing the hype. “We’re not using these technologies just because it’s cool; we’re focussing on the requirements of our business fields.”

Super, computer!

A good business-focussed example is Airbus Smarter Fleet™, a cloud-based service platform developed by Airbus with the help of IBM. Smarter Fleet provides Airbus customers with various solutions, including intelligent maintenance and engineering tools, increased flight efficiency and optimised fuel consumption. Jaime Baringo and his team at Airbus in Toulouse are working to expand these services using AI.

Until now, computers have only been able to provide solutions to known problems with known root causes. IBM Watson, however, can do more than that. “It can process huge volumes of data and discover new, previously unknown root causes by establishing correlations that a human would never come up with,” explains Baringo. For example, Watson determined the precise relationship between the temperature and early wear of brakes. “This is a completely new finding, which will allow Airbus to develop prognostics that help airlines avoid delays,” Baringo continues.

According to Baringo, the potential of AI for Airbus can be best illustrated using the A350 XWB as an example: the aircraft has some 50,000 sensors on board and collects 2.5 terabytes of data every day. If you let AI loose on this data, then problems and correlations can be recognised faster and aircraft maturity can be achieved more quickly.

Chasing the clouds

A further area where deep learning has made considerable progress is in image recognition – and the Group is benefitting here, too. Since 29 September 2016, ‘One Atlas’ has been providing employees and customers with a large database of satellite images that can be accessed online. However, before these images from space end up in the database, clouds need to be identified and removed.

“That’s a lot harder than it sounds,” says Laurent Gabet, who manages optical research and development at Airbus Defence and Space. In fact it is sometimes very difficult to determine, even for the human eye, whether a particular area on a satellite image is cloud or snow.

Airbus Defence and Space uses an algorithm to identify these objects, but it has an error rate of 11%, which has prompted Gabet and his colleagues to test the deep-learning platform TensorFlow. This open source software from Google can be used and changed by anyone; Google provides the toolbox for others to work with. TensorFlow analyses a large number of images, looks for recurring patterns, and uses this to learn how to identify objects by itself.

In the TensorFlow test phase, the error rate has already improved to just 3%. Gabet is convinced that these new applications will make a huge difference: “Now that these programmes are freely available, the field of image recognition will progress in leaps and bounds and open up new opportunities,” he says.

AI, we have a problem

AI has achieved amazingly good results in many areas, but for Fehling, that is its biggest weakness. During a chat in his Munich office, he talked about the great potential of deep learning and new AI technologies, but he also pointed out a problem. Deep Learning and the other AI systems like Google’s TensorFlow, DeepMind typically have one thing in common: the knowledge they collect is hidden behind incredibly complex structures that are often difficult to analyse.

In addition, there are some AI issues that have yet to be clarified. What happens if something goes wrong? Does responsibility lie with the algorithm? Or with the person who developed it? “That’s why we are taking AI step by step,” he says. In the first instance, AI systems should provide help and support – without taking control. Developers inside the Group are already working on the next steps; for example, they are exploring ways in which AI can help make UAVs and passenger aircraft even safer.

Detlev Konigorski, Gunnar Haase and Andreas Poppe (from left to right) with individual printed parts of the four-metre-long THOR project aircraft

AI, take over please

Some of the answers to how this works can be found at Airbus in Hamburg. Standing in front of a pile of white plastic parts, a smiling Detlev Konigorski explains: “Yes, that’s right: we’re going to make a plane from all of this.” The developer is currently constructing a new THOR test aircraft with with his emerging technologies and concepts team at Airbus – and the parts that his colleagues are dragging into place behind him are all fresh from the printer.

THOR completed its maiden flight in November 2015, making history as the first 3D-printed aircraft. The next version features a new capability: it will be able to fly by itself – piloted by AI. This technology could potentially be used in a passenger plane in instances when the pilots are unable to fly due to a fall in cabin pressure. This is the moment when AI would take over. AI is better than its human counterparts at weighing up a multitude of factors in a short space of time – and then calmly making the most appropriate decision without panicking.

To land a plane safely, AI must be able to correctly identify whether the terrain is suit-able for landing or whether what is in front of it is actually a body of water. The aircraft will be equipped with optical-recognition scanners and lasers for this purpose. The required algorithm is being developed and tested in collaboration with the German Research Centre for Artificial Intelligence.

The initial THOR flight with AI at the controls is scheduled for the beginning of 2017. Konigorski is already convinced: “With AI on board we can make an important contribution to aviation safety,” he says.

THOR makes its maiden flight in Stade, Germany, on 21 November 2015

Choose your friends carefully

In addition to the work being carried out by Airbus engineers, Airbus Ventures, the venture capital fund set up by Airbus in Silicon Valley and Europe, is on the lookout for promising investment opportunities in this sector.

But the hype surrounding this topic doesn’t make it an easy task. “There are countless start-ups out there, all claiming to have the best AI solutions,” says Maryanna Saenko, investment partner at Airbus Ventures. “Some investors pump millions into these start-ups without knowing how the companies differentiate themselves, their approach to the market, or what the end result will likely be.”

Airbus Ventures is not one of them, explains the engineer and robotics specialist. Its team is only interested in those start-ups that operate in areas of strategic interest to the Group. This includes fields such as digital manufacturing, logistics, connected fleets and urban air mobility.

And just like other big technology companies, the Group is also investigating the value of using virtual assistants. After learning from blue collar workers on the shop floor, such helpers could make a difference to manufacturing and maintenance by providing assistance and even making recommendations. This is further evidence that Airbus is investing in a vision far removed from science fiction and AI hype – a vision where humans and AI together create solutions that guarantee more efficiency and safety in the aerospace sector.

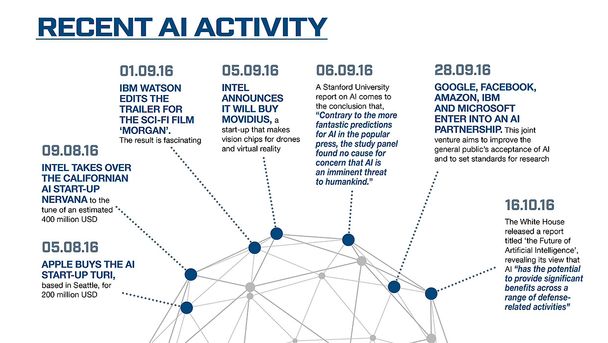

Recent AI activity

Lars Thomsen predicts future trends – and doesn’t need a crystal ball to do this. Every year the futurologist travels around the world and interviews 400 experts in the field working on technologies that will shape our future. His speciality: artificial intelligence.

With your knowledge of what’s in the pipeline, is it worth investing in AI?

Absolutely. AI is set to cause major disruption in most industries over the next few decades: it will solve a whole series of problems that cannot be resolved today. AI can help interpret complex climate models and it can find ways of using raw materials in production, as well as natural resources such as water, more efficiently.

How far ahead can you foresee what will happen?

We’re talking about up to ten years into the future.

And will we have developed machines more intelligent than humans by the next decade?

That depends on the application. In ten years there will be self-driving cars that can drive better than most people, but does that make them more intelligent? No. In most branches of industry, the objective is to get machines to take care of time-consuming, routine tasks to enable us to concentrate on more important things. AI could, for example, read your emails and compile suggested replies while you are asleep. Then, when you wake up, all you have to do is press the ‘send’ button.

What is the potential for AI in the aerospace industry?

It’s vast. AI can increase safety in our overcrowded airspaces by supporting air traffic controllers. It can detect material defects in production and help to develop lighter aircraft with longer service lives that use less fuel. And it can improve the flight experience. We have all found ourselves sitting next to an interesting person on a flight. But these encounters don’t have to be left up to chance. Airlines can seat people whose profiles are compatible next to one another.

Do you think AI will fly planes one day?

It’s very likely that we will see self-flying parcel delivery UAVs in the next ten years. And if passenger planes can fly more safely with AI on board, we will be doing the same before long. We humans have an innate desire for innovation and we are forever striving to make our lives safer and more comfortable.

Beata Cece